Laboratory NDT systems for Ultrasound Thermography

Ultrasound-excited thermography is a non-destructive testing method that is very well suited for the characterisation of non-metallic and metallic structures. The method is particularly used when defects are to be detected that can be activated by the introduction of sound. These include, in particular, cracks and bonding defects. The method is used both in production and in the laboratory. This testing method can be easily integrated into series testing with the help of automatic handling machines. UTvis is expandable with all other Edevis excitation sources and software modules.

UTvis – Advantages for complex construction & metal parts, inspection for cracks, defects

- Ultrasound-excited lockin thermography is a defect-selective testing method

- Ideal for the characterisation of complex components for crack and defect detection

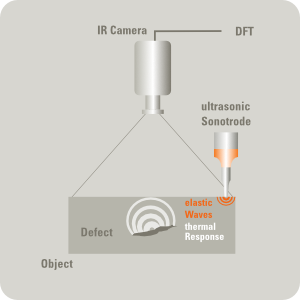

Principle of Ultrasound Thermography

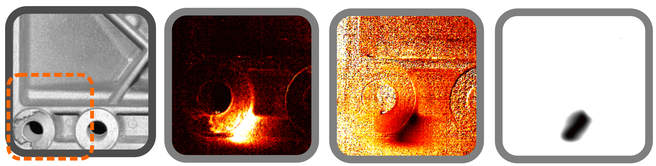

In ultrasound thermography, the examined object is exposed to high-power ultrasound. Material disturbances such as cracks or other mechanical interfaces create friction losses in the material. This causes “hot spots” to form on the surface, which are detected with an infrared camera. The sensitivity of the method can be significantly increased with the phase technique. Here, the intensity curve of the surface temperature is spectrally analysed by means of the Fourier transformation and broken down into a phase and amplitude image. In the phase image, interfering effects resulting from different emission coefficients or inhomogeneous excitation are significantly reduced.

Applications

- Crack testing on metallic and non-metallic materials

- Bond test on material composites

- Corrosion detection

- Testing of adhesive joints

- Testing of joint connections

- CFRP / other fibre composites (delaminations, impacts)

UTvis Software

The UTvis software module for DisplayImg allows ultrasonic burst and lock-in measurements as well as frequency sweeps. Amplitude (=power) and frequency modulation are used simultaneously to create the best possible acoustic conditions, and thus defect-selectively bring the material defects to light.

The software parameterizes the edevis ultrasonic generators via the serial port, and controls the excitation power and frequency during the measurement with high time accuracy via the analog interface of the Edevis Signal Generator (ESG). After the acquisition, the power delivered by the power generator is read back, allowing the acoustic coupling quality to be checked. All parameters and result values are stored as metadata with the resulting measurement image files.

The UTvis module is available within the DisplayImg Professional environment, and also can be used in the automation software as well as in the DisplayImg API programming interface.

Related Software products:

Technical Data

| Ultrasound generator | UTvis 4000 |

| Power output | 4 kW |

| Power supply | 400 V / 16 A |

| Freuency modulation | 15 kHz – 25 kHz |

| Overload protection | yes |

| Housing | 19” / 3 HU |