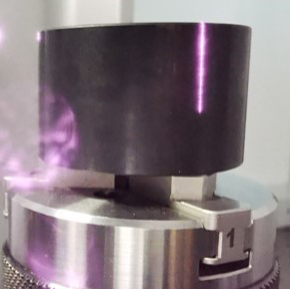

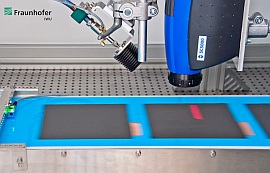

Non-metallic materials such as silicon nitride, ferrite or graphite are increasingly used in industry due to their mechanical or electrical properties. In order to ensure the service life for certain applications, quality assurance measures are taken. If you want to replace the time-consuming dye penetrant inspection with a residue-free and automatable method for crack detection, laser scanning thermography is the right choice. Even parts with complex geometries can be subjected to a full inspection with it – and non-destructively.

MoreSuccess Stories

Thermographic inspection of electronic components: for example, potting compounds in stators of electric motors

Electronic components are often encapsulated in high-temperature-resistant electrical potting compounds to protect them from wear and tear and extend their service life. However, defects in the potting compound can lead to premature failure of components, such as stators of electric motors. Random testing using laser scanning thermography provides the best insight to avoid failures at this point.

MoreTesting welded battery contacts in automotive batteries with thermographic methods

With the massive increase in sales of electric cars, scalable fully automated testing of battery cell contacts is becoming increasingly important. The cells are usually connected by laser or ultrasonic welding. If a welded contact is not made properly in the process, the entire battery can fail. But how do you check a number of several hundred welding points reliably and quickly? Laser thermography enables such an inspection in a non-contact, non-destructive, reliable way – and in less than a second.

MoreSurface crack testing of induction-hardened components, e.g. parking lock wheels and individual cams of camshafts

Steel components in the engine and transmission sector are often induction hardened to increase the mechanical load capacity of the surface. Defects in the hardening process can lead to cracks, which must be excluded for quality and safety reasons. The edevis inline inspection technology replaced the labor-intensive magnetic particle inspection at two automotive supplier companies and reduced cycle times to a few seconds.

MoreWeld seam inspection for complex small components, e.g. a high-pressure injection nozzle for diesel engines

Automated weld seam inspection with thermographic inspection methods is also possible for small and complex parts. In the case of a high-pressure injection nozzle for a diesel engine, two individual parts are joined together with three laser beam welds. In the event of a defect, the weld seams may show cracks. Defects and leaks would be the consequences. An inline crack detection system based on induction thermography was developed with the manufacturer.

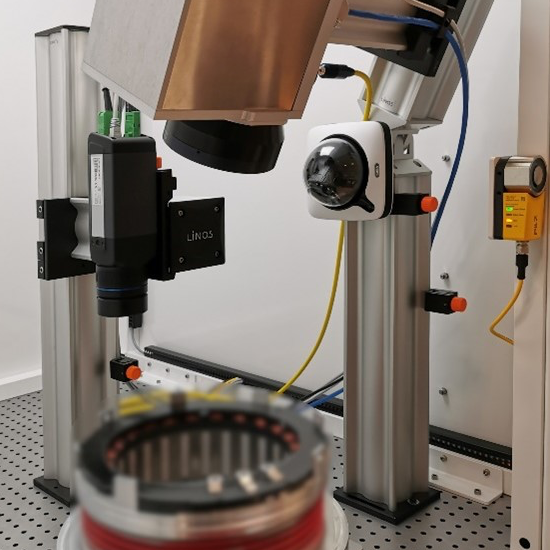

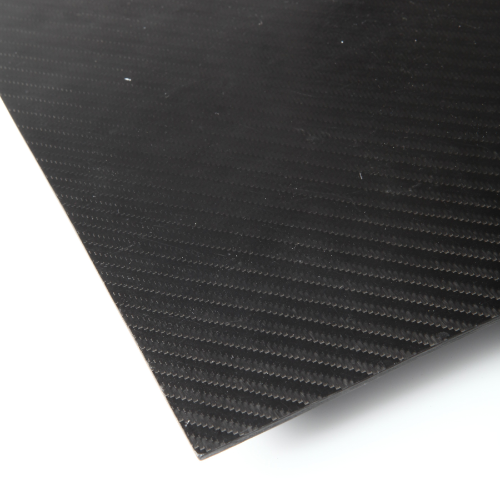

MoreThermographic testing of CFRP structural components in motorsports

The use of carbon fiber reinforced plastics (CFRP) is indispensable in professional racing to push the performance limits of vehicles. Maximum weight savings while ensuring the desired functionality are the focus of design and product development. In addition to flow-optimized aerodynamic components, structural components such as complete chassis (monocoques), chassis parts and transmission and unit carriers are primarily made of CFRP. These are often hybrid components that utilize specific advantages of different materials to increase mechanical component properties.

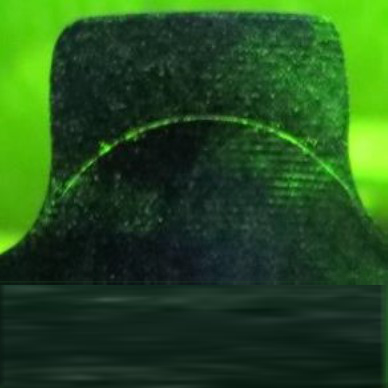

MoreAutomated contact pattern inspection of gears in series production with infrared thermography

The contact pattern of gears reveals the points at which power is transmitted when the tooth flanks mesh. If the contact pattern in the test deviates too far from the specified optimum contact pattern, the gear is readjusted or rejected. Conventional testing with spotting paste is time-consuming and cleaning-intensive, and only reflects the sum imprint. The newly developed thermal inline contact pattern inspection from edevis, on the other hand, inspects the contact pattern in the load test rig quickly, residue-free, fully automatically and can evaluate each tooth pair individually if required.

MoreBetter safe than sorry: Quality inspection of bicycle parts, e.g. frames, handlebars and other carbon components

More and more bicycle manufacturers are realizing that they can save themselves material defects, part breakages and serious accidents with thermographic inspections and thus meet the quality requirements of their customers. This is because defective parts and processes can be detected automatically and non-destructively: whether in development by means of laboratory testing, in production by means of random sample test stands and in large-scale series production by means of inline testing systems with short cycle times. edevis has a wide range of experience for the bicycle industry. In most cases, these are defects that are not visible to the naked eye because they are hidden inside the parts.

MoreFor lifelong durability: thermographic testing of ceramic brake discs

Ceramic brake discs ideally last the life of a car. Their manufacture, and in particular the production of the friction layer for the brake discs, requires special know-how and consistent quality assurance. One part of this is testing with active thermography. The main aim here is to ensure that the friction layer is securely bonded to the supporting body.

MoreOut of the box: Testing the correct application of adhesive in paperboard boxes for cosmetic tissues

Paperboard boxes for cosmetic tissues are convenient for consumers, but sometimes challenging for producers: the delicate paperboard boxes are subjected to considerable stress when the tissues are pulled out. Thermographic inspection systems from edevis therefore ensure that the adhesive seams are present and correctly positioned. The containers are inspected inline in the glued state within a tenth of a second. Defective ones are sorted out. In general, adhesive, sealant or coating inspections are predestined applications for thermographic methods.

MoreParticle detection in mini rechargeable batteries by laser thermography

Mini-batteries for in-ear headphones or hearing aids are, just like all other batteries, subject to a danger: If the smallest particles sneak in between the electrode strips during production, this can lead to short circuits during operation. An edevis inspection system uses laser thermography to check for particle contamination, thus ensuring that the customer’s production processes are validated.

MoreLaser weld seam inspection of complex components: e.g. car seat backrests with more than 50 welding points

Even in the case of complexly shaped components, automated weld seam inspection with thermographic inspection methods is easily possible. One good example are car seat backrests, where several steel sheets are joined together at more than 50 welding points. In the event of an accident, the backrest must withstand the force, what must be tested in terms of safety. Together with the client, a new robotic test cell was developed for manufacturing.

More