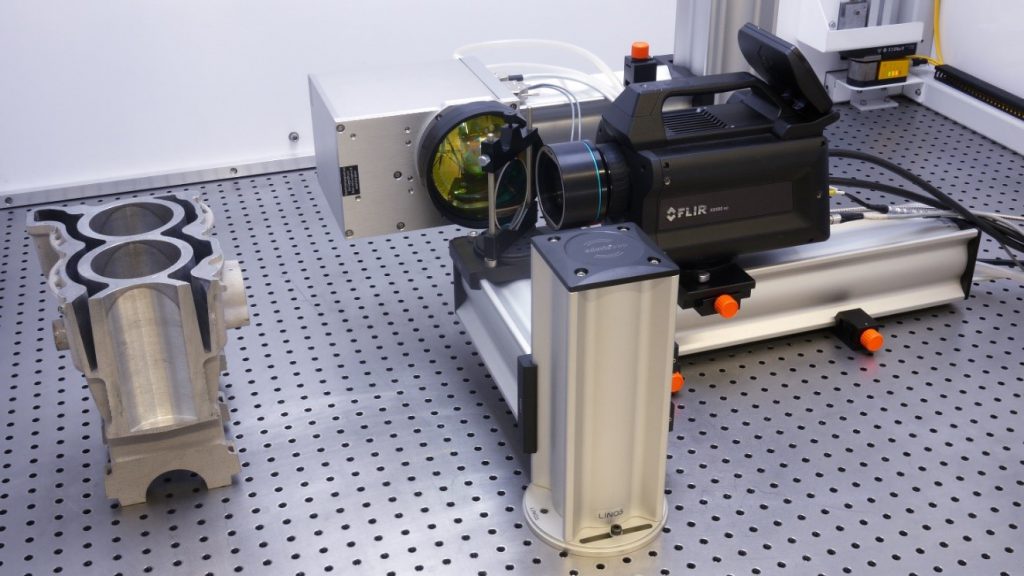

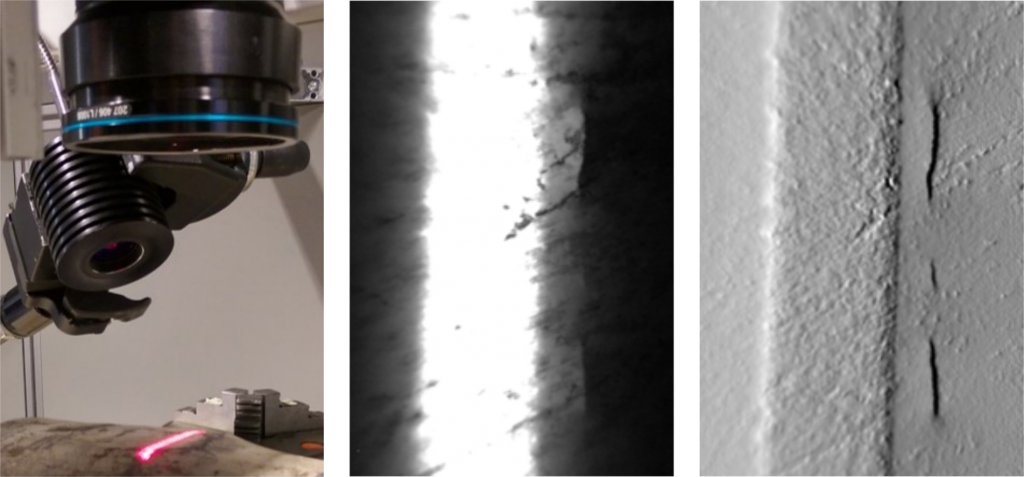

Laboratory laser scanning thermography system

Laser scanning thermography is a non-contact, non-destructive testing method that is very well suited for crack detection in various materials, especially plastics and ceramics. The method is image-based and works well even under difficult environmental conditions. LTscan is expandable with all other Edevis excitation sources and software modules.

LTscan – non-contact crack detection, without any chemicals

- Laser scanning thermography is a non-contact testing method

- Ideal for crack detection in non-conductive materials

- Suitable for complex surface geometries due to collinear setup

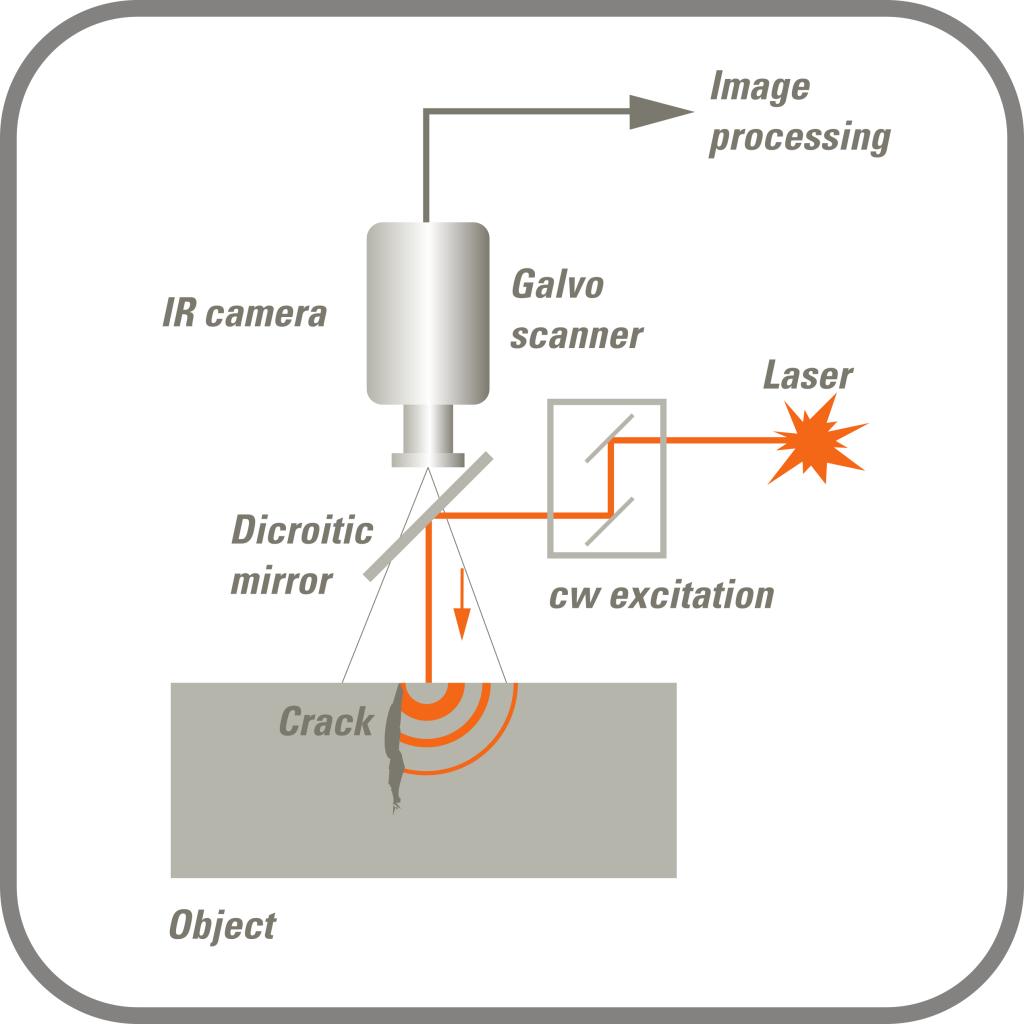

Principle of laser scanning thermography

Laser scanning thermography – also called flying spot thermography – is based on the relative motion between the excitation laser and the component.

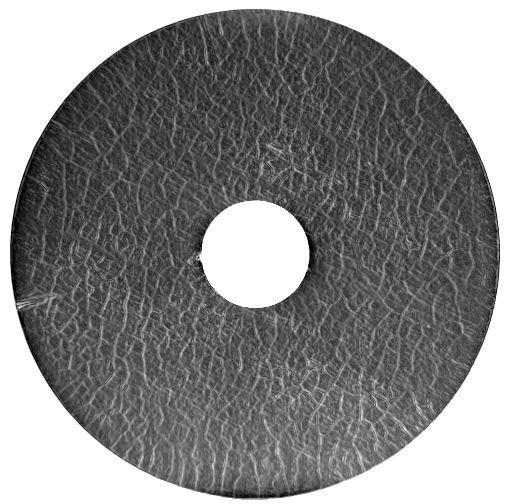

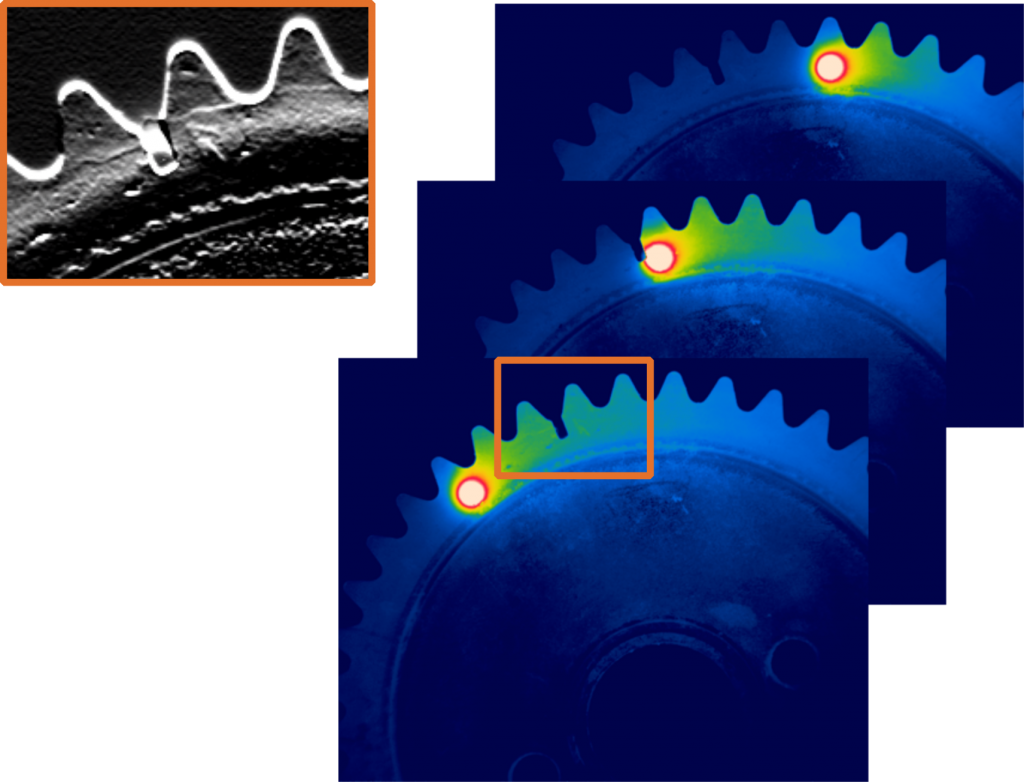

A laser point heats surface of the examined object. The lateral heat flow emanating from this point is stopped by thermal interfaces such as cracks. Due to the accumulating heat, the cracks can be detected by an infrared camera without contact. To inspect the entire component surface, the dot is moved across the surface by a galvo scanner. For large-area inspection, a laser line can be generated by fast periodic scanning in one direction, which is slowly moved over the component in the orthogonal direction. Depending on the component geometry, either individual points or contours can be scanned.

As an alternative to the galvo scanner, the line can also be generated via an optical element and the relative motion can be generated by means of rotation or translation axes. Combinations of galvo scanner and axes have also already been implemented industrially.

Typical applications of scanning laser thermography

Applications:

- Detection of cracks, adhesion issues or pores in potting compound

- Detection of contamination on electrodes

- Crack detection in green bodies and sintered parts

LTscan Software

DisplayImg Software Module LTscan

The LTscan software module enables the controlling of edevis lasers and a galvo scanner. Both safety aspects and the parameterization of the laser and scanner are controlled by the software, and edevis lasers of the FL and NT types are supported. This allows for the definition of important parameters such as laser power, scan speed, scan field size, scan direction and scan mode. Various scanning patterns such as points, contours and areas can be defined.

The software parameterizes the edevis laser via the serial port and controls the positioning of the scanner axes during the measurement. The scan controller card controls the excitation power of the laser via its digital interface. All parameters and result values are saved as metadata with the measurement result image files.

The edevis laser safety cabin effectively protects against laser radiation and ensures safe working without further protective equipment (laser safety goggles). The built-in safety PLC and locking of the pneumatic lift doors results in the highest possible work safety.

At the same time, the integrated optical stage enables professional test setups. The optionally available additional modules “X95” and “Mikrobank” enable an efficient setup with further optical components in the beam path.

The optionally available monitoring camera provides continuous insight into the measurement process.

Technichal data

| Laser | LTscan 100 NT | LTvis 50 FL |

| Output power | 100 W | 50 W |

| Wavelength | 938 nm | 1070 nm |

| Fibre adapter | F-SMA | – |

| Working distance | 150 mm | 400 mm |

| Scanning area | 50 x 50 mm2 | 130 x 130 mm2 |

| Cooling | Luft / Wasser | Luft / Wasser |

| Power supply | 230 V / 16 A | 230 V / 16 A |

| Housing | 19” 4 HU | 19″ 3 HU |