Laboratory NDT systems for pulse thermography

Pulse thermography is a non-contact testing method that is ideally suited for the non-contact characterisation of thin layers or coatings / lacquers and delaminations. The very short test duration and the high detection sensitivity make pulse thermography an extremely powerful tool in non-destructive materials testing. The pulse-phase evaluation technique allows the quantitative determination of material properties such as thickness, porosity or thermal conductivity. In addition, disturbances such as varying surface properties or uneven heating are suppressed. The interpretation and documentation of test results is very simple. The PTvis system, which is based on high-power flash lamps, has a modular design and can be expanded with further types of excitation (UTvis, ITvis, OTvis…).

Principle of pulse thermography

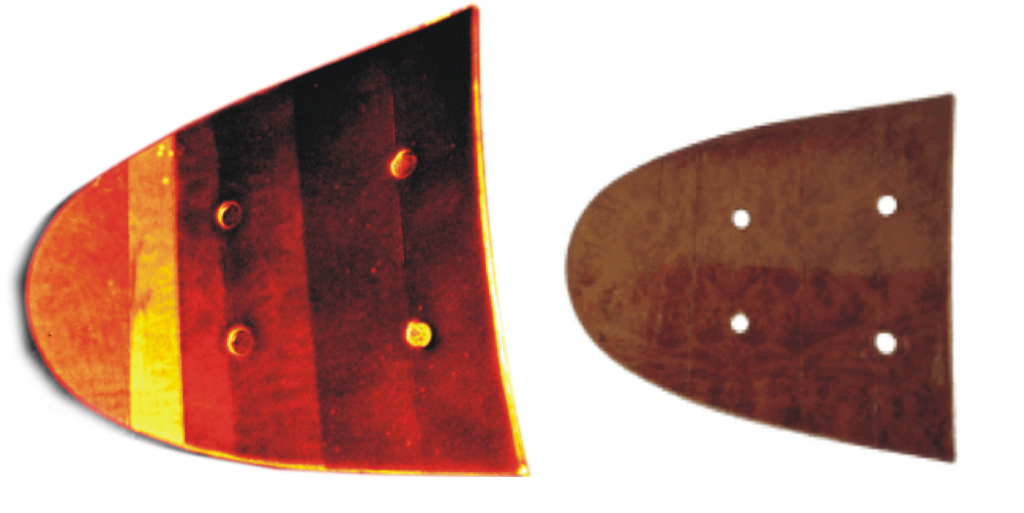

The surface of the examined object is heated strongly for a short time with flash lamps. In pulse thermography, the heat flow caused by the short flash plays an essential role. Thermal obstacles (e.g. thickness variations or material defects) change the heat flow. Temperature differences form on the surface, which are recorded with a high-speed infrared camera. The sensitivity of the method can be further increased with pulse-phase technology. Here, the intensity curve of the surface temperature is spectrally analysed by means of the Fourier transformation and decomposed into a phase and amplitude image. With the help of calibrations, the phase image allows quantitative statements to be made about certain material properties.

Applications

- Coating thickness testing and paint thickness measurement

- Non-destructive surface testing

- Detection of corrosion under paints, detection of filiform corrosion.

- Testing of layers and coatings, bonding test

- CFRP / other fibre composites (delaminations, impacts, inclusions and porosity, bonding of inserts, resin/fibre content, preform analysis…)

- Wall thickness measurements

- Testing of bonded joints

- Weld seam inspection

PTvis Software

DisplayImg Professional

The comprehensive acquisition and evaluation software with project tree and script interface, modularly expandable with all further excitation modules.

Zum Produkt »

Technical Data

| Flash generator | PTvis 3000 | PTvis 6000 | PTvis 12000 |

| Flash energy | 3 kJ | 6 kJ | 12 kJ |

| Power supply | 230 V / 16 A | 23 0V / 16 A | 230 V / 16 A |

| Output channels | 1x 3 kJ | 1x 6 kJ or 2x 3 kJ | 2x 6 kJ or 4x 3 kJ |

| Housing | compact housing | 19” unit with 6 HU or stand alone unit | 19” unit with 12 HU or stand alone unit |

| Real time synchronization | yes | yes | yes |

| Suitable for continuous operation | no | yes | yes |

| Connector for standard flash lamps | yes | yes | yes |

| Connector for linear flash lamps | no | yes | yes |

| Dimensions | 34.5 x 19.5 x 28.5 cm | 19″, 6 HU, 475 mm depth | 19″, 12 HU, 475 mm depth |

| Weight | 9 kg | 29 kg | 58 kg |