Laboratory testing with Induction Thermography

Induction thermography is a non-contact, non-destructive testing method that is very well suited for the non-contact and imaging characterisation of metal structures as well as metal-polymer composite materials. The method is particularly used when a non-contact measurement technique with short measurement times is required, e.g. for crack detection. Induction thermography is very robust and also works under difficult environmental conditions. The method is used in production as well as in maintenance. In contrast to dye penetrant testing or magnetic particle testing, the test specimens are tested completely without contact and without the use of chemical additives.

ITvis – Extremely fast testing of metallic components, cracks, seams etc.

- Induction thermography is a non-contact testing method

- Ideal for crack detection or testing of welds

- Detection of smallest defects

- Excellently suited for inline testing in production

Crack testing every second

This inspection method can be excellently automated with the help of robots, for example, and with short cycle times. With image processing optimised for thermographic inspection, material defects can be found and evaluated fully automatically. ITvis is expandable with all other edevis excitation sources and software modules.

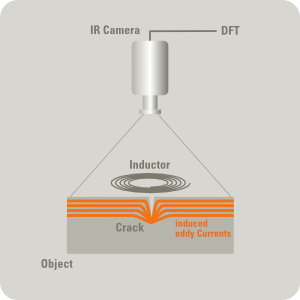

Principle

The surface of the examined object is heated by means of induction. The resulting current density distribution in the material is damaged by cracks or other irregularities such as overrolling. Heat backpressure causes “hot spots” to form on the surface, which are detected with an infrared camera. The sensitivity of the method can be significantly increased with the phase technique. Here, the intensity curve of the surface temperature is spectrally analysed by means of the Fourier transformation and broken down into a phase and amplitude image. In the phase image, interfering effects resulting from different emission coefficients or inhomogeneous excitation are significantly reduced.

Applications

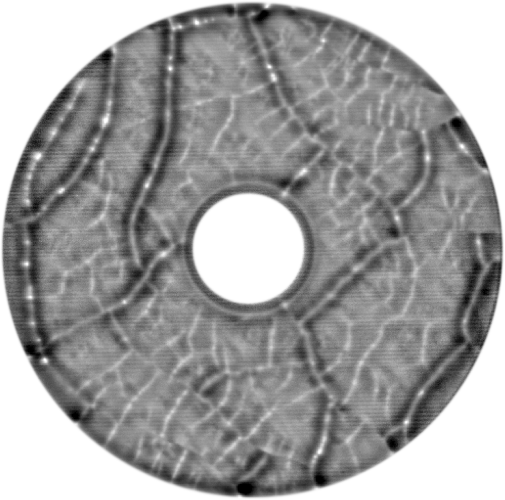

Crack testing with induction thermography on standard test specimens. Fast non-contact measurement without auxiliary materials.

- Surface defects

- Crack detection

- Detection of overrolling

- Joint connections

- Weld seam inspection

- Braze seam inspection

- Adhesive joint inspection

ITvis Software

The ITvis software module for DisplayImg allows induction pulse and lock-in measurements. Induction power and frequency are fully software controlled to obtain the best possible measurement results, and thus bring the cracks to light up.

The software parameterizes the edevis induction generators via the serial port, and controls the excitation power with precise timing via the ITvis interface of the Edevis Signal Generator (ESG). After the acquisition, the status of the induction generator is read back, allowing to validate the proper deposition of the induction pulse. All parameters and result values are stored as metadata with the resulting measurement image files.

The ITvis module is available within the DisplayImg Professional environment, and also can be used in the automation software as well as in the DisplayImg API programming interface.

Related Software products:

Technical Data

| Induction Generator | ITvis 3000 MHF | ITvis 5000 MHF | ITvis 10000 HF |

| Power | 3 kW | 5 kW | 10 kW |

| Frequency range | 6 kHz – 60 kHz | 15 kHz – 60 kHz | 50 kHz – 450 kHz |

| Power supply | 230 V / 16 A | 400 V / 16 A | 400 V / 32 A |

| Cooling | Air | Air | Water |

| Overload protection | yes | yes | yes |

| Housing | 19” | 19” | 19” |