Automated crack detection with induction thermography – ITvis ACD

Fully automated crack detection – a competitive advantage for you

ITvis ACD is the fully automatic crack detection system for detecting e.g. hardening cracks on forged components.

The test system is offered as a semi-automated or fully automated version. Depending on the test stand version, the parts can be fed either automatically via a conveyor or manually. The evaluation of the test results is always fully automated with machine learning algorithms, i.e. without the user’s intervention.

A single crack inspection takes less than 0.1 seconds and can be integrated into the process cycle in most applications. The robustness of the inspection method against irregularities in the material and contamination is very high compared to e.g. eddy current inspection, and the pseudo-rejection rate can be kept very low by using suitable image processing. Even more complex component geometries can usually be inspected.

In practice, an ITvis ACD thermographic inspection often replaces one or more magnetic particle inspection stations, and is thus extremely cost-efficient and benefits with a rapid payback.

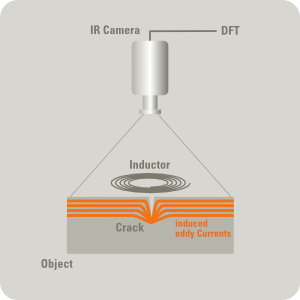

Principle of the induction thermography test system

Induction thermography is a non-contact, non-destructive testing method that is very well suited for the non-contact and imaging characterisation of metal structures as well as metal-polymer composite materials. The method is particularly used when a non-contact measurement technique with short measurement times is required, e.g. for crack detection. Induction thermography is very robust and works even under difficult environmental conditions, and is suitable both in production and for maintenance. In contrast to dye penetrant testing or magnetic particle testing, the test specimens are tested completely without contact and without the use of chemical additives.

A test takes between 0.1 seconds and several seconds, depending on the material type and thickness. Ideally, the test takes place stationary, but can also be carried out in continuous motion if necessary.